Variable speed is the new norm. Everything that functions in heating, ventilation and air conditioning requires a motor that moves air or water to transport heat, and the speed, the velocity, matters. Now that the power to adjust speed is accessible, we have options, we have range, we have Design Envelope, and specifically, the Compass circulator.

The Compass Circulator by Armstrong technology is a product of Design Envelope. The two models, Compass R, a dry-rotor circulator, and Compass H, a wet-rotor circulator, are both universally compatible, variable speed circulators that can replace any fixed-speed circulator by Armstrong and most competing models. These modern replacements are energy efficient, easily installed, and highly advanced as seen by their wide range of flexibility between head and flow.

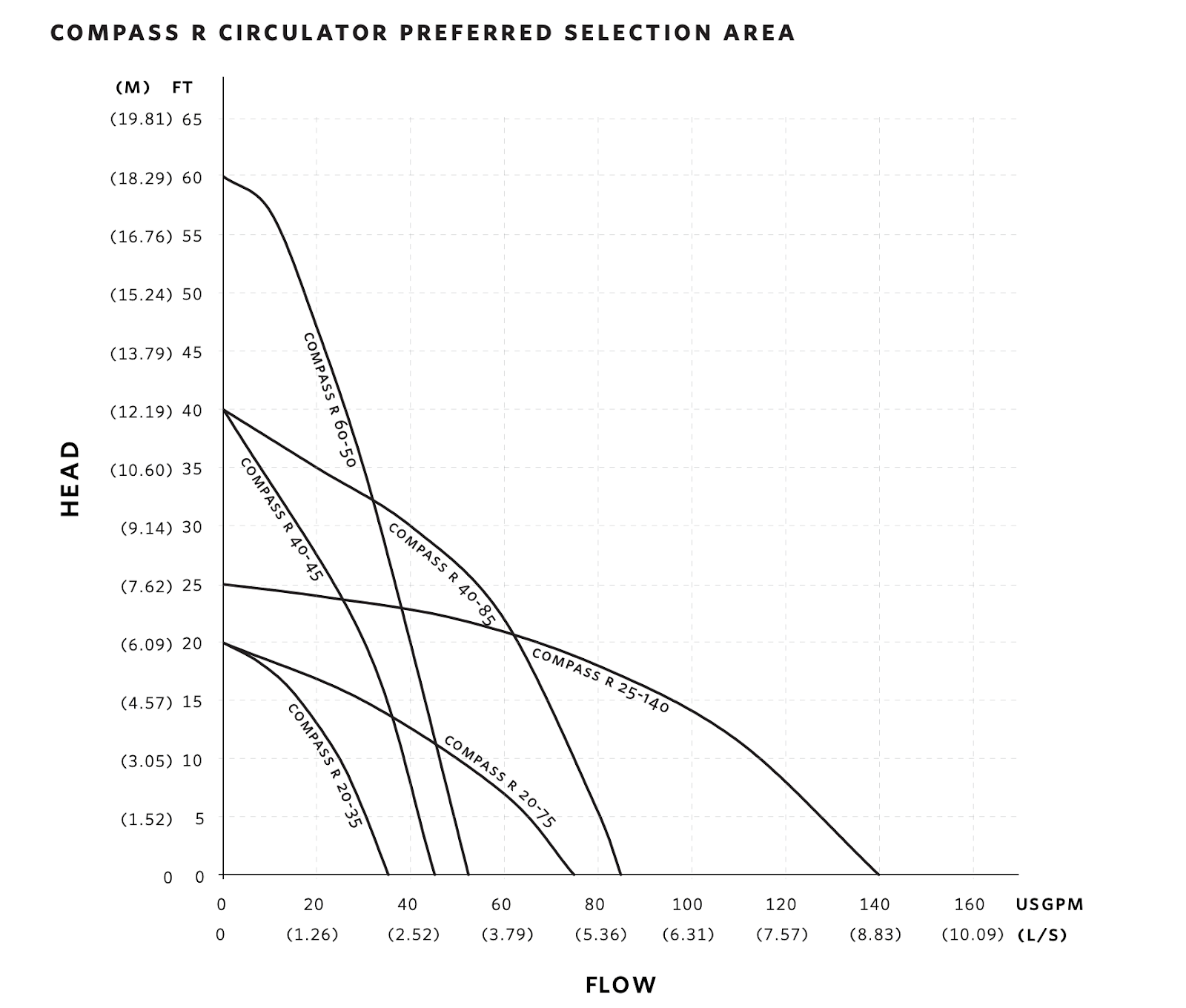

Design Envelope has its name because the products in this collection envelope (as a verb) a wide range of power and compatibility with the dynamic of flow versus head, or gallons per minute (GPM) and pressure.

(Figure 1) source: Armstrong Fluid Technology, Compass dry-rotor circulator submittal

Compass R

As seen above in the graph showcasing the relationship between head and flow, the Compass R model exists between the range of 60 ft and 140 GPM. There are different operating modes, represented by each of the lines in figure one. According to Armstrong, they have four sensorless modes and three fixed speed modes

Compass R is a dry-rotor circulator, meaning the motor never comes in contact with fluid. Dry-rotor circulators are slightly noisier than wet-rotor circulators, but they are equally efficient. This motor would replace similar fixed-speed dry-rotors and is easily installed.

Maintenance can be more difficult, but the dry-rotor choice is beneficial because they are not afraid of airing and they are less affected by the abrasion of water. They are a great choice for an open heating system. Additionally, Compass R circulators save up to 70% in energy cost in comparison to their fixed speed circulator counterparts.

Compass H

The wet-rotor circulator, Compass H, has similar Design Envelope benefits of the expansive versatility of function. These circulators have two sensorless modes, two constant pressure modes and three fixed speed modes. Wet rotors, unlike dry rotors that do not come in contact with water, have low noise levels and do not require lubrication. They also require little maintenance. However, it is important they are installed in a closed heating system, as the presence of abrasive parts can be damaging.

According to Armstrong, Compass H circulators save 50% or more over fixed speed circulators in operating cost, electrical energy and carbon emissions. They have a total of nine different modes of operation to suit system requirements.

Benefits of Compass circulators

Both of the Design Envelope Compasses, R and H, are universal replacements for all circulators in their capacity range. They are the perfect replacement for a wet-rotor or dry-rotor with fixed speed. Their popular flange-to-flange dimensions allow for easy installation for an open or closed heating system.

The equipment has a clear display of analog input for external speed control and power consumption. The machinery is offered with cast iron or stainless steel volutes, and the flange kits come with two flanges, hardware and gaskets. The different Compass H and R models are offered in cast iron, lead-free bronze and lead-free union fitting sets.

Installation and Specs

On Armstrong’s website, all of the products’ specifications and installation details can be easily found. These documents spell out model dimensions and include pictures for safety and sizing. Information can be found on the benefits and features, design and submittals, typical specs, warranties and installation instructions.

Northrich Co. trusts Armstrong Fluid Technology to provide high-quality, long-lasting machinery for commercial and residential heating and cooling. To learn more about variable-speed Compass circulators and to get started on the transition to or installation of variable-speed equipment, contact Northrich Co. at 216-581-4750 or go to www.northrich.com.