The world is shifting into sustainability. There is more access to technology that allows for energy efficiency, there is more education, there are more resources and there is no reason not to make this change now that the tools one needs are within arm’s reach. It would be foolish not to make this extra effort, and the newest standards for energy efficiency practically make it a requirement. Variable Frequency Drives (VFDs) are the new norm.

Most HVAC standards come from the International Energy Conservation Code (IECC) or the Air Conditioning, Heating and Refrigeration Institute (AHRI) that has its most recent standard 90.1. These standards mandate minimum energy efficiency for equipment such as chillers, condensing units and air-cooled heating pumps. There are different requirements for full-load (FL) and integrated part-load conditions (IPL).

VFDs allow motors to be part-load because they change the energy frequency to be adjusted to various speed settings. Without VFDs, motors, when turned on, will jump start to their full-capacity of speed, even when it is often not needed, becoming a waste of energy that does not need to consistently be on full blast.

According to CSE Mag, IPL efficiency requirements take a weighted average of the equipment’s relative efficiency at various load levels. This resulting average is a more accurate representation of real-life application. All of these standards found in IECC and AHRI are for motors, and there are not yet specifications for VFDs, but the conditions make it so that the only way to meet standards is with the application of VFDs.

The recurring theme of the motor standards from IECC and AHRI is the reduction of flow to 50%, and the power at half speed should be no more than 30% of that required at full speed. It might seem unrealistic to reduce the power of a motor to less than 30% when the speed is only cut down 50%, but with VFDs, this is possible thanks to the Cube Law.

The Cube Law

The flow within a pump is proportional to the speed. We subtract the reduction of speed from 100%, so if speed is reduced by 10%, the resulting flow is 90%. The torque, or a force producing rotation, is the result of the speed squared, and the power usage is the result of the speed cubed.

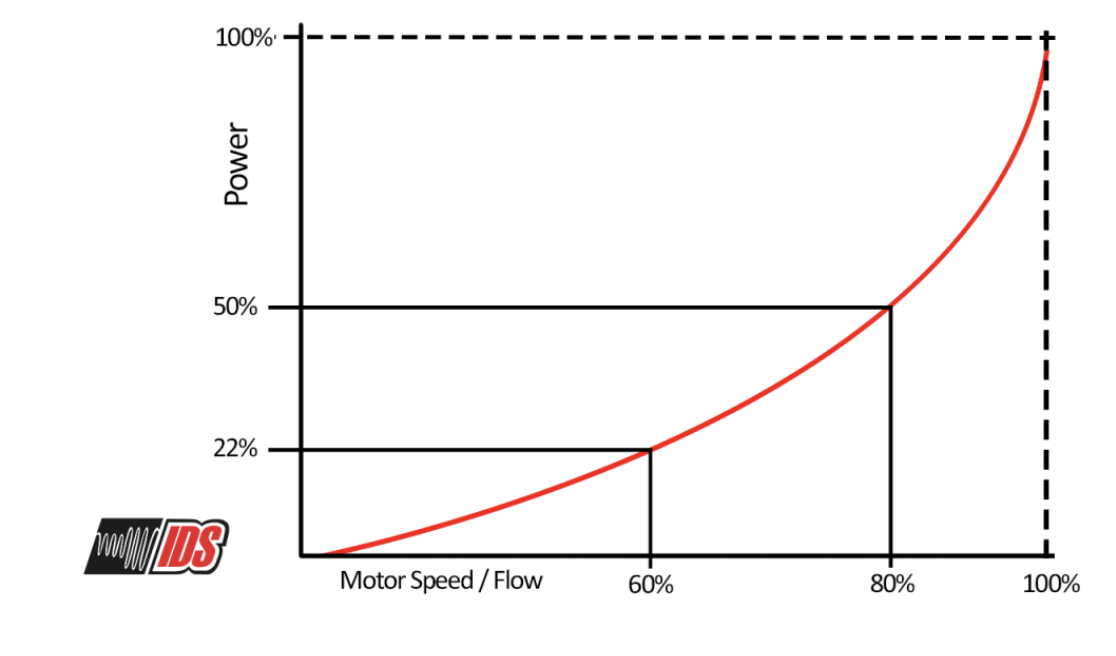

If a pump is slowed down by 20%, the resulting flow is 80%, or 0.8. To calculate the power one would solve 0.8 cubed (0.8 x 0.8 x 0.8) to get 0.512, about 50% of the power.

The efficiency of a pump reduced to 50% of power with a 20% reduction in speed. Source: IDS

If the speed of a pump is cut in half, an ability that is required by HVAC standards, the power is calculated by solving 0.5 cubed (0.5 x 0.5 x 0.5) to get 0.125, or 12.5% of power. This is clearly less than 30% of power. Power is money as well as energy, making VFDs remarkably cost and energy efficient.

Additional standards

As outlined by CSE Mag, both ASHRAE standard 90.1 and the EICC have the following standards that make it clear VFDs are implied:

- Pumps in hydronic systems with a combined motor capacity of 10 hp or larger need to automatically vary fluid flow by no less than 50%.

- Under Standard 90.1, the individual motor ≥5 hp in hydronic variable-flow systems with a total system power exceeding 10 hp must also meet the 30% power at 50% flow requirement.

These requirements have not been updated since 2021 and were mostly put in place around 2016. New, accessible standards would most likely clarify VFDs as normal practice and have more clear standard usage incorporated. It is clear, however, that most traditional machinery for HVAC pumps does not meet the requirement of 30% power consumption at 50% flow and speed. The following equipment and machinery do not meet these requirements.

- Air foil fan with discharge dampers

- Forward curved fan with discharge dampers

- Air foil fan with inlet guide vanes

- Forward curved fan with inlet guide vanes

- Vane-axial fan with variable-pitch blades

Any fan with variable speed control meets requirements. VFDs are not a new concept, but they are becoming more and more prevalent in the HVAC industry, as we can see from the requirements. As this technology expands and becomes more efficient, it can reduce power and slowly begin to eliminate the costs at hand on consumers and the toll on environmental sustainability. No one wants to use too much power, now they aren’t allowed, and with VFDs, no one has to.

To learn more about VFDs and how you can incorporate them into your HVAC experience or purchase variable speed equipment, contact Northrich Co. at 216-581-4750 or go to www.northrich.com.