As an HVAC/R professional or a building operator, you may face issues in the refrigeration part of your system such as high suction pressure. Without good understanding of the refrigeration cycle and what is happening in each process, you will be spending more time guessing rather than solving the problem.

For this reason, we will first examine the refrigeration cycle and then discuss high suction pressure. To be confident of what we are doing, we always ask the good question "why?" as it helps us discover the root of issue we face.

What is the refrigeration cycle?

But again how can we start talking about refrigeration cycle without understanding some basic rules in thermodynamics. First law of thermodynamics: the energy can’t be neither created nor destroyed, but can be changed from one from to another. Second law of thermodynamics: heat always transfer from the material at higher temperature to material at lower temperature.

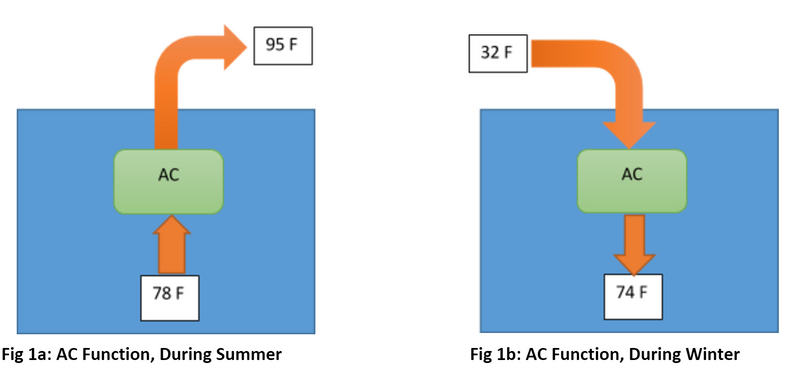

Now that it is closer to summer, we need to remove some heat from the space to keep the room temperature at 78 F, outside it is 95 F. Let’s think about it again, we want the heat to transfer from the cold space to outside (hot), this is what the AC does. It removes heat (unwanted) from the heat from a cold space (source) to a hot space (ambient) which will not be affected (sink).

In winter, the AC brings heat from a cold space at 32 F (unwanted) to a hot space at 74 F where we need it. Now we understand the theory behind the AC, now we will look in details to the components and processes of the AC for better understanding of each process.

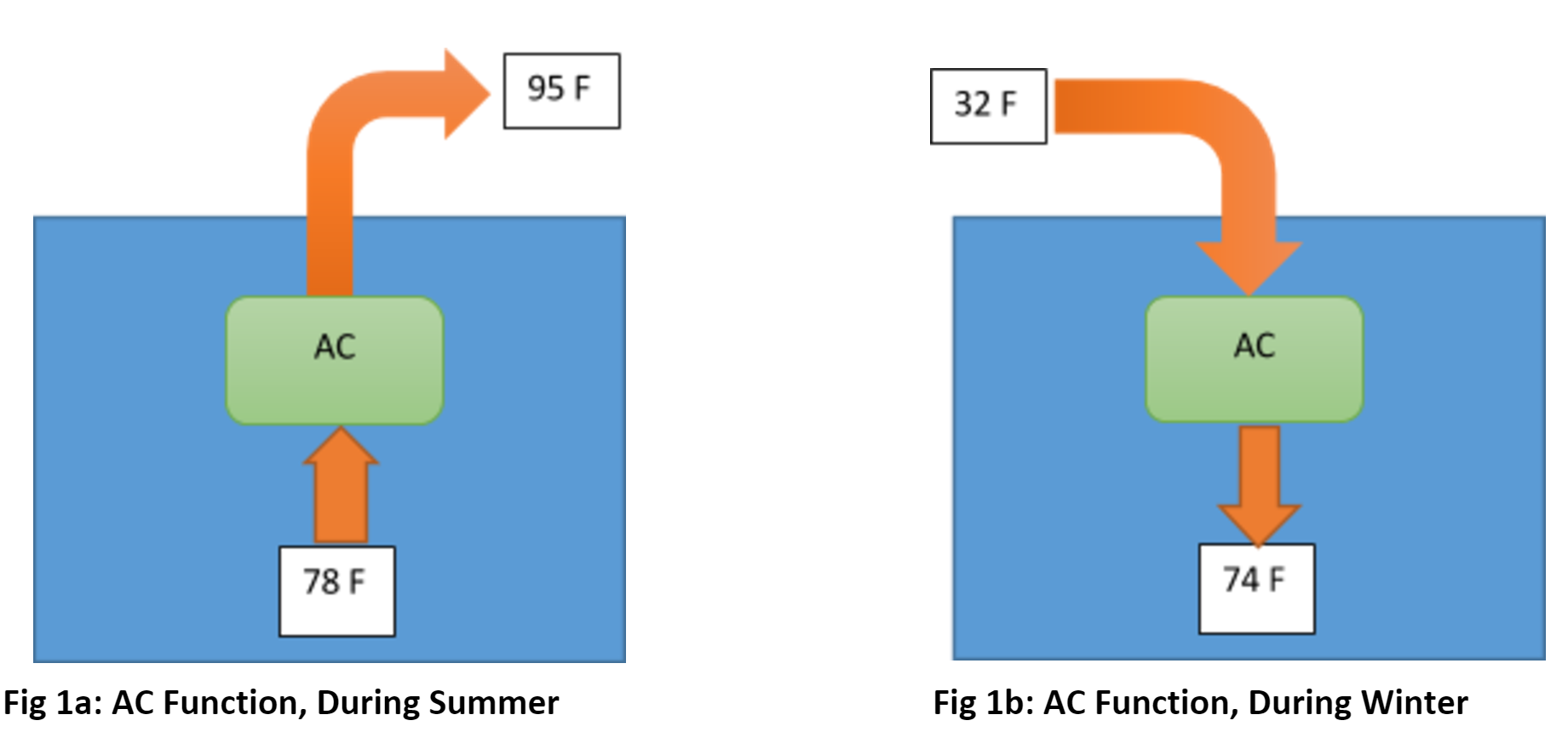

Each AC unit contains four main components and other accessories. The four components are: compressor, evaporator, throttling device (thermostatic expansion valve “TEV”) and condenser. Another tool will help us to understand the refrigeration cycle is the Pressure-Enthalpy (P-h) diagram. But before proceeding we will take a minute to explain what the enthalpy is. Enthalpy is the total heat content of a system. Clear? No! Let’s imagine we are adding heat to a cold water, by the definition of the enthalpy as we add more heat the enthalpy of the water will increase as well. For example we start the heating process of the water at initial temperature 25C, the corresponding enthalpy at this temperature is 104.83 KJ/kg. As we add more heat enthalpy will go up for example at a temperature of 95 C, the corresponding enthalpy is 398.09 KJ/Kg. How we get those values? It’s easy! Just search for water properties on the internet you will find water properties tables.

Fig 2: AC-Refrigeration Cycle Main Components

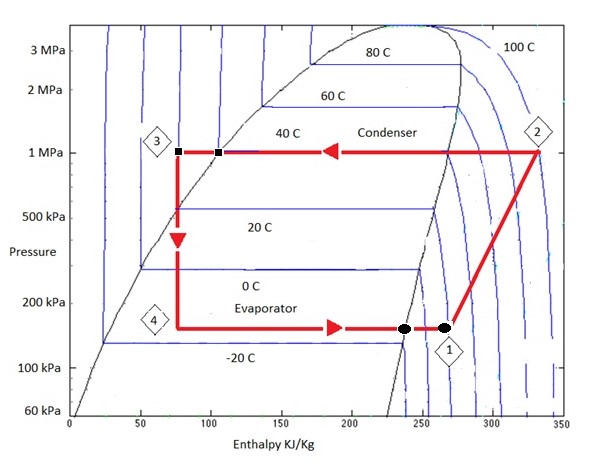

1-2 Compression: The inlet of the compressor is a refrigerant in the superheat state at low pressure (here is the problem we are trying to talk about in this article. Will come to it later on). The compressor deals only with substances in their gaseous status. By compressing the superheated refrigerant (gaseous status), the pressure and temperature increase to a point high pressure/temperature line. The main function of the compressor is to circulate the refrigerant in the system and provide sufficient amount to handle heating/cooling loads (assuming the system is charge with sufficient amount of refrigerant)

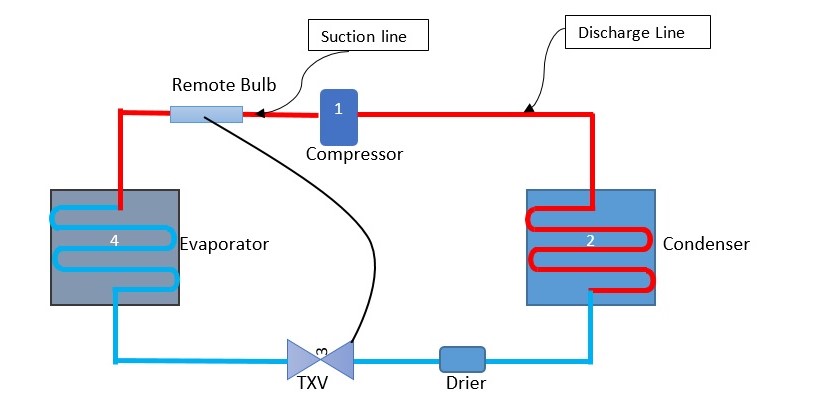

2-3 Condensation: This process takes a place in the condenser, which is nothing but a heat exchanger, where superheated (vapour) refrigerant flows in the coil, the refrigerant temperature is higher than the cooling fluid temperature (it will lose heat). The heat will transfer from the refrigerant to the cooling medium. Refer to Fig 5, the condensation occurs between the points 2 and 3 at constant pressure 1 MPa, the temperature drops from 100 C at point 2 to 20 C at point 3. The final state of the refrigerant is subcooled, which means all quantity of the refrigerant at this point is in liquid state. There are two common cooling mediums, air and cooling water.

A. Air Cooled Condenser: cooling medium is the ambient air, with the help of fans the air flow over the condenser coil, allowing the refrigerant to loose heat. See Fig 3a. Example of air cooled condenser is the outdoor unit of split unit AC, which contains the condenser.

B. Air Cooled Condenser: cooling medium is the water, with the help of pumps the cooling water flow over the condenser coil, allowing it to loose heat. See Fig 3b. Example of water cooled condenser is water cooled chillers for industrial project, where the cooling water is available from nearby lake or any other sources.

3-4 Expansion: In this process a throttling device is used to reduce the pressure of the refrigerant from the discharge pressure (point3) to the suction pressure (point4). No heat transfers from/to refrigerant so this process takes a place at constant enthalpy. As a result of reducing the pressure, the temperature also will drop from 20 C at point 3 to -18 C at point 4. The final state of refrigerant at this process is mixture of vapor and liquid.

4-1: Evaporation: This process takes place in the evaporator, which is nothing but a heat exchanger, where the mixture of liquid-vapor refrigerant flows in the coil, the refrigerant temperature is less than the temperature of the medium to be cooled. The heat will transfer from the medium to be cooled to the refrigerant, resulting in heating the refrigerant. As it get heated, by the end of the process will be converted totally to vapor (superheated). Refer to Fig. 5 at point 4 the temperature is -18 C and by the end of the process at point 1 the temperature is 20 C. This process occurs almost at a constant pressure which is the suction line pressure 160 kPa.

Again, there are two common mediums to be cooled, air and water.

A. Evaporator air cooler: medium to be cooled is air, with the help of fans the air flows over the Evaporator coil, and cooled by the flowing refrigerant. Refrigerant will gain heat. See Fig 4a. Example of evaporator air cooler is the indoor unit of split unit AC, which contains the evaporator.

B. Evaporator water cooler: medium to be cooled is water, with the help of pumps the water flows over the Evaporator coil, and cooled by the flowing refrigerant. Refrigerant will gain heat. See Fig 4b. Example of evaporator water cooler is chiller unit, where it is used to cool water (chilled water) then distributes it to the space or product to cool it.

Fig 5: P-h Diagram of a Refrigeration Cycle for R-134a (Modified from this chart)

What is superheat?

Before starting to analyze our problem (high suction pressure), an important but confusing term should be addressed to be able to understand all terms in the problem analysis.

Superheat: Superheat is a measured value. It is the difference between two temperatures. Superheat is measured as the difference between the actual temperature of the refrigerant vapor and the saturation temperature of the refrigerant at that same point.

Refer to Fig. 5 on the evaporator side, process 4-1, there are two black circles, simply superheat is the difference between those two points.

At the beginning of the evaporation process the refrigerant is at liquid-vapor mixture state, then the refrigerant will start to gain heat from the medium to be cooled, the temperature of refrigerant will remain the same (saturation temp) till at some point in the evaporator the mixture liquid-vapor will totally converted to vapor (the left side black circle), after this point the temperature of refrigerant will increase to the superheat temperature at the inlet of the compressor ( point 1, the right side black circle).

How do we measure it? Put a thermistor or thermocouple at the evaporator outlet to get the evaporator outlet temperature (this is the right side black circle), a pressure gauge at the same point as the temperature reading, you know your refrigerant then you have your refrigerant saturation temperature-pressure table? If not, simply google, they are available on the internet. From the pressure reading you have, you find from the tables the corresponding saturation temperature (the left side black circle), now you have the two points, take the difference and the result is the superheat.

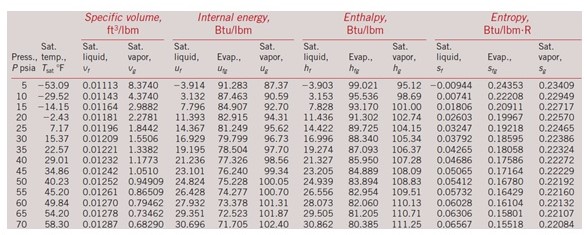

Example: Your temperature reading at the outlet of the evaporator is 30 F, and you pressure gauge reading is 25 psi, from the table below at P = 25 psi, the saturated temperature = 7.17, then the superheat = 30 – 7.17 = 22.83 F.

Refer to Fig.2, the remote bulb controls the TXV based on a predetermined superheat temperature, if the sensed temperature exceeds the predetermined value it means not enough refrigerants flowing to meet the cooling load, so the remote bulb moves the EXV in the opening direction to allow more refrigerant to flow. If the sensed temperature by the bulb is less than the predetermined value it means refrigerant flowing in the evaporator is more than what is required to meet the cooling load, so the remote bulb moves the TXV in the closing direction.

This is very important, as it may cause many problems. (For more information check Danfoss 067L5955, 1.5 - 3 TON TXV R410A)

Table 1: R134a Saturation Properties pressure table (Reference: www.chemours.com)

Back to the problem at hand

For any refrigeration cycle/AC unit there are two operating pressures: suction pressure and discharging pressure, high and low settings for each pressure line determined by the manufacturer will stop the unit.

Case 1: Insufficient compressor (leaking discharge valve). In other words the compressor can’t provide the needed refrigerant to the evaporator to handle the cooling load. Resulting in higher temperature and pressure at the outlet of the evaporator, causing high suction pressure.

Case 2: Suppose we checked the compressor discharge valve, the compressor piping and the amperage and all are fine. Let’s do the analysis again, at the outlet of the evaporator the refrigerant leaving at high temperature, the remote bulb should react and move the EXV to the opening direction to allow more refrigerant to flow in the evaporator to handle the cooling load. If the temperature and pressure at the outlet of evaporator (suction pressure) keeps going up, that meant we have a problem with the EXV and could be one of the following:

A. The settings for superheat is not correct.

B. The EXV is not working properly and to be replaced. Be sure to select the right size for the right refrigerant.

C. The EXV is undersized, when it is fully opened can’t pass the required amount of refrigerant to the evaporator coil to handle the cooling load requirements.

Case 3: We checked all of the above, and everything seems to be fine. May be the condenser is dirty? If the condenser is dirty then the refrigerant can’t reject the design amount of heat to the cooling medium, resulting in higher temperature than the design temperature at the inlet of the evaporator, higher temperature at the inlet will lead to higher outlet temperature and pressure and high suction pressure occurs.

Case 4: Let’s consider the dryer in our analysis, we did talk about it before, but it’s simply a holding vessel receives the liquid refrigerant from the outlet of condenser. See Fig. 1, its primary function is to make sure only liquid refrigerant reaches the expansion valve, it also contains a desiccant, a moisture absorbing element to help dry out the refrigerant. If the dryer is clogged (full of moisture) less liquid will pass through it, then less will reach to the evaporator, higher temperature and pressure at the outlet will be high (high suction pressure).

Case 5: If there is moisture in the system, it may cause freezing of the EXV in the opening position.

Case 6: If the condenser is air cooled type, then the fan should be sufficient enough to remove the heat from the refrigerant at the location ambient temperature.

Case 7: If the condenser is water cooled, then the cooling water temperature and flow rate should be sufficient to remove the heat from the refrigerant, so it leaves the condenser in subcooled state and at the design temperature.

Case 8: In all of the above cases, we assumed high superheat, higher temperature leads to higher pressure at the section line. But there are another factor can cause high suction pressure and low superheat. This factor when the system is overcharged of refrigerant, overfeeding the evaporator with refrigerant leads to higher suction pressure.

Case 9: Oversized EXV leads to overfeeding the evaporator, hence, increasing the suction pressure.