Hydronic boilers switch on and come to life, beginning to heat up water. That water turns to heat energy. The heated water flows through pipes and radiators to warm your building through cold nights and winters. But, how does the water get hot, through heat transfer devices called hot water heat exchangers?

Well, your options are simple; there are only two ways the water is heated in the heat exchangers; water in tubes, with a heat source surrounding the tubes, or fire in the tubes with water surrounding the tubes. Here are the main differences between firetubes and watertubes, what you need to consider and the future of boiler designs with developing technology.

Firetubes

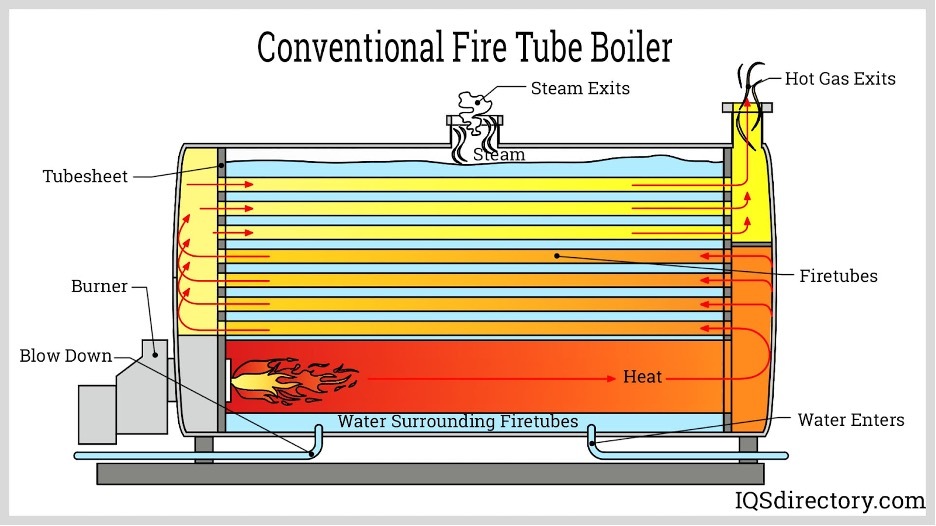

With either selection, we have a standard boiler design: a large tank for water mass, often called the “heat exchanger”. The difference, however, lies within. Inside of a firetube boiler heat exchanger is water filled almost to the top and thin steel tubes running long-ways. A standard firetube boiler has three or four passes. Each “pass” is a completed passage of hot exhaust gas through the water from within the tubes. More passes result in more opportunities for thermal energy to permeate into the water.

The hot air starts from the burner and fan and works its way through the tubes where it is eventually released through an exhaust at the top of the tank. These boilers have a simple and efficient design; however, they have some faults. According to a blog from Ware Inc., when compared to their watertube counterpart, these boilers are less efficient at generating heat, and the larger quantity of water filling up the tank results in a larger environmental impact as well as more space needed for operation.

However, firetube boilers have a lower total cost of ownership, easier access and maintenance and they can easily handle large loads of surge or pressure, as mentioned in a blog from Industrial Boilers due to having a greater mass of water.

Watertubes

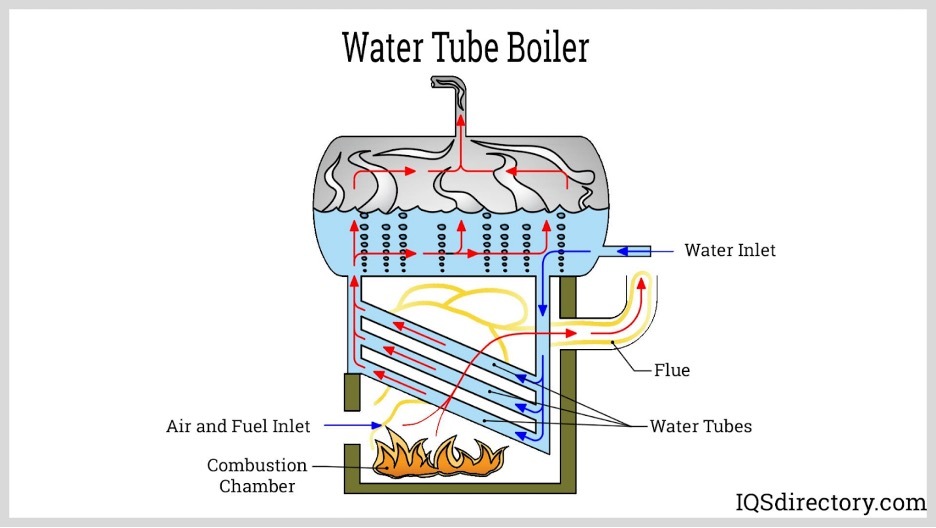

Now that we know firetubes have tubes of hot gas surrounded by water, it’s easy to imagine the opposite. Watertubes create steam by passing water through tubes surrounded by combustion gases. The intention of heating water remains the same while the structure and function is reversed. The tanks and tubes are both thinner, and can operate at higher pressures and temperatures, making them more suitable for larger, industry-level steam production.

According to the blog from Industrial Boilers, they have a faster heat recovery and turn down. Since the tubes are thinner and the surface area of water in contact with hot air is higher, the water can heat up much faster, allowing it to generate more steam per hour than firetube boilers. As seen from the graphic below, the water can also very easily be recycled and has a self-sufficient multi-pass process. As the heated water moves up through the tubes and a portion of it exits as steam, the remaining water is quickly pushed back down to re-pass over the combustion chamber.

Evolving Technology

With artificial intelligence (AI) quickly developing, things are becoming more efficient in every realm of HVAC technology, including boilers. (Note: this blog was not written with the use of AI). Boilers, with the help of AI, can be transformed into self-regulating systems.

According to an article from Ross on the latest boiler technology, “smart” steam boilers have sensors to monitor temperature and pressure as well as AI powered controllers to maintain premium efficiency while minimizing heat and energy losses. Anytime heating or cooling equipment is more closely monitored and regulated, the outcomes become more efficient. AI-monitored boilers could recognize the standing temperatures of a space and meet specific needs with curated steam production.

Apart from AI, boiler technology is meticulously navigating the recycling process of exhaust air to reduce waste. Boilers that recycle water tend to be hot water condensing boilers, slightly different from typical boilers. This technology is able to reuse combustion gases that would typically exit through exhaust after transferring heat. However, by capturing latent heat, these condensing boilers significantly reduce the carbon footprint of boilers.

By reducing the waste of combustion gas, energy costs are lowered while heating one’s home or building throughout the winter months, and less gas is released and added to the air we breathe.

Additional sustainable technology includes furnaces fueled by 100% hydrogen or biomass, replacing gas or coal. There are also a variety of other renewable energy sources such as solar-powered boiling systems, geothermal steam systems and modular systems made of multiple smaller units to reduce energy consumption and allow for flexibility based on steam demand.

Conclusion

Watertube and firetube boilers are just as cool as they sound! There is a clear difference between the two and based on maintenance abilities and the size of the space one hopes to utilize with a hot water boiler, one boiler type might be more efficient. In the end, both boiler types will produce the same outcome, and the real technology efficiency can be found in the versatility of environmental energy sources that can easily be manufactured with boiler technology.

As you deliberate your future boiler purchase and incorporation into a residential or commercial HVAC system, look at both firetube and watertube boilers, as well as their friendly, energy source alternatives.

For more information on steam boilers, contact Northrich Co. at 216-581-4750 or go to www.northrich.com.